Cyclic Materials Plans $82 Million Rare Earth Recycling Campus in South Carolina

Cyclic Materials will invest more than $82 million to build a rare earth recycling campus in McBee, South Carolina, expanding its U.S. footprint as manufacturers and policymakers push to reduce dependence on overseas supplies of critical minerals, the company said in a statement, with details confirmed by industry reporting.

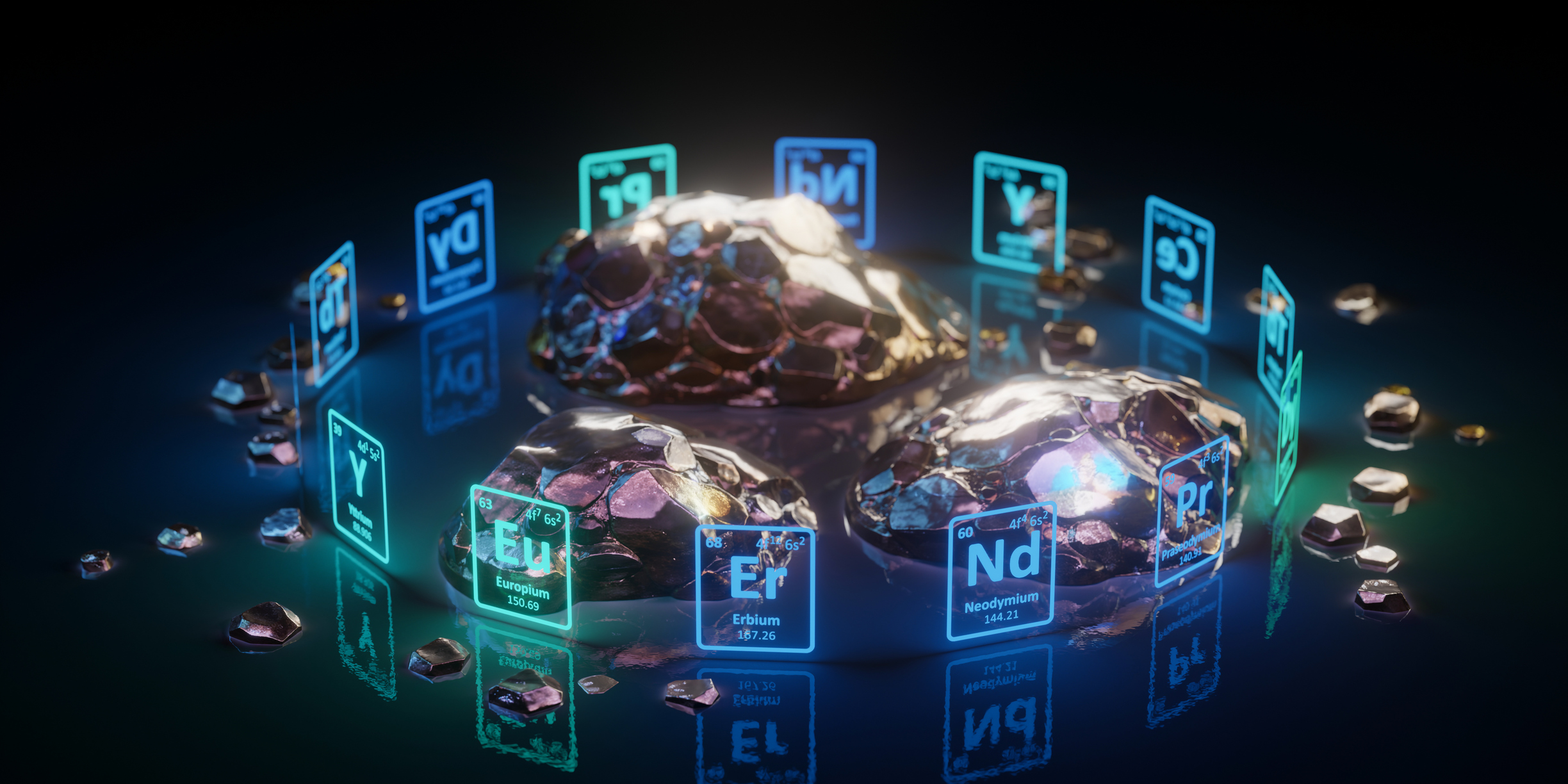

The project comes as the United States intensifies efforts to secure domestic sources of rare earth elements used in electric vehicles, wind turbines, defense systems, and advanced electronics. For decades, global supply has been dominated by mined and processed material from China, while recycling rates for end-of-life magnets have remained minimal, analysts say.

Cyclic Materials plans to combine a “Spoke” preprocessing plant with its largest “Hub” facility to date at the South Carolina site. When fully built, the campus is designed to handle up to 6,000 tonnes of magnet material annually, up from an initial 2,000 tonnes, and to produce as much as 1,800 tonnes of mixed rare earth oxides per year using the company’s proprietary MagCycle and REEPure technologies. Company estimates indicate that output would be equivalent to the rare earth content required for roughly 6 million hybrid vehicle transmissions annually.

Industry observers note that recycling-based supply chains can be developed far faster than traditional mining projects, which often take more than a decade to permit and build. Cyclic Materials said operations at the South Carolina campus are expected to begin in 2028, with more than 90 skilled jobs created, supported in part by state and federal incentives.

The announcement follows a long-term commercial agreement signed in late 2025 with magnetic materials producer VACUUMSCHMELZE. Under the 10-year exclusive deal, Cyclic Materials will recycle all magnet manufacturing scrap generated at VAC’s new Sumter, South Carolina facility, which began operations at the end of last year. Together, the two sites are expected to form a regional cluster for rare earth magnet recycling and production, according to company disclosures.

Analysts say the focus on heavy rare earths is particularly significant, as these materials are among the most supply-constrained and difficult to source outside China. Recycling magnet scrap and end-of-life products offers one of the few near-term pathways to increase availability without new mining, they add.

State officials welcomed the investment, citing its alignment with South Carolina’s push to attract advanced manufacturing and clean-energy supply chains. Industry groups have also argued that regional recycling hubs could help stabilize prices and reduce geopolitical risk for downstream manufacturers.

Cyclic Materials is positioning the South Carolina campus as a cornerstone of a broader North American recycling network, according to the report. Backed by a $75 million Series C round led by T. Rowe Price and supported by strategic investors and industrial partners, the company aims to scale recycled rare earth output as demand from electric mobility, data centers, and renewable energy continues to rise.

Source: Cyclic Materials

SUNSHINE Spotlight: The South Carolina project signals a shift toward recycling-led rare earth supply chains as the U.S. seeks faster, domestic alternatives to traditional mining.