PureCycle and Brückner Advance BOPP Film Trials Using Recycled Resin

PureCycle Technologies announced the successful completion of large-scale production trials of its PureFive™ resin in biaxially oriented polypropylene (BOPP) film, marking a new milestone in the use of recycled materials for high-performance packaging.

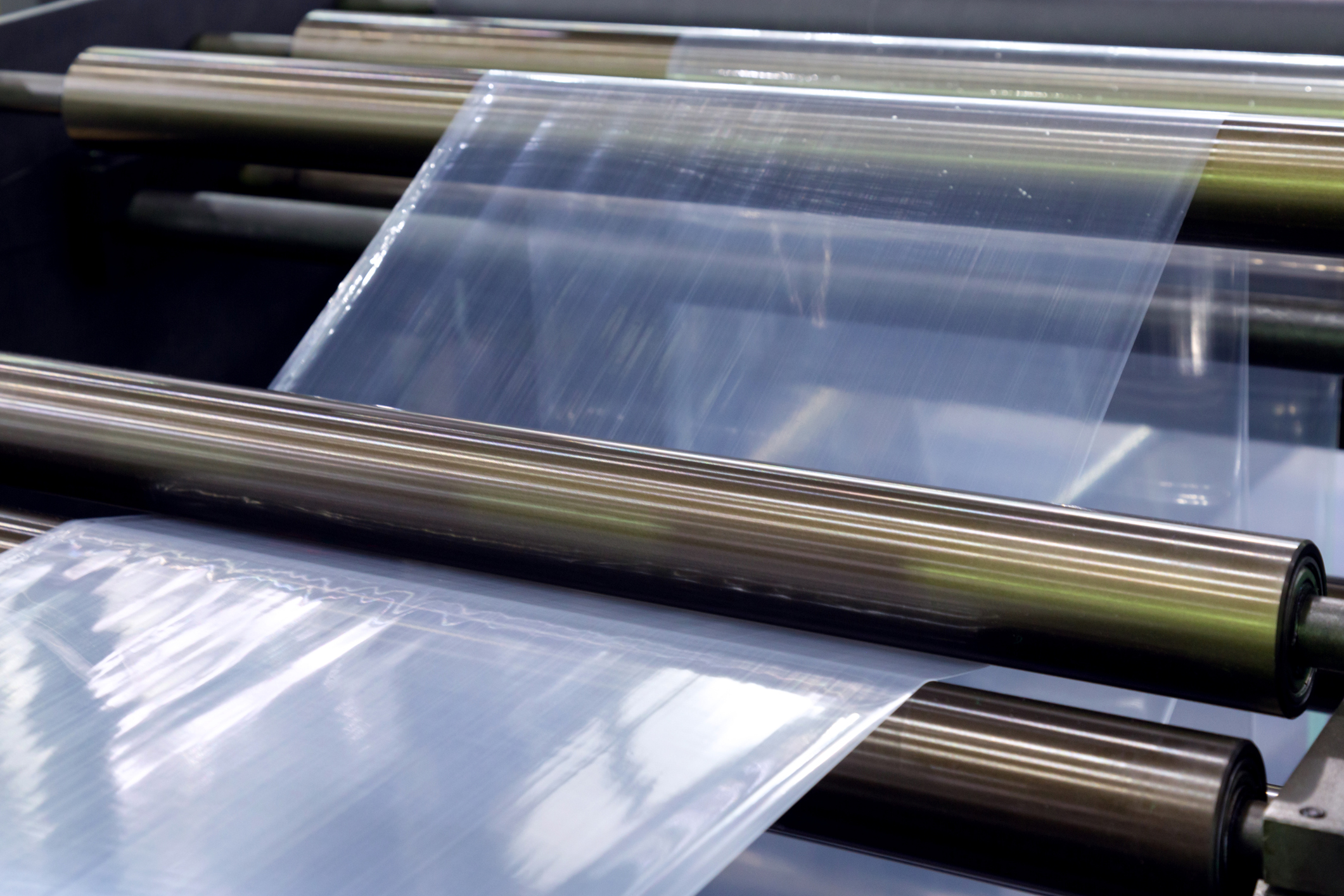

According to the company’s statement, the trials took place in August at the facilities of Germany-based Brückner Maschinenbau GmbH, a global leader in film stretching technology. Over the course of two days, approximately 16,000 meters of BOPP film, nearly one meter wide and in varying thicknesses, were produced at industrial speed.

The results, according to PureCycle, showed that PureFive Choice™ resin, which contains 50% post-consumer recycled (PCR) content, performed on Brückner’s production line much like virgin polypropylene, even when running at 40 meters per minute. Two different types of film were produced: a 25-micron multi-layer film commonly used in food packaging and a 50-micron film designed for labeling applications. PureCycle has begun distributing the samples to potential brand partners for further testing.

“We are thrilled by the results of these latest trials with Brückner,” said Dustin Olson, CEO of PureCycle. Dr. Markus Koppers, Head of Brückner’s Technology Center, called the achievement “a big step forward for the industry.”

The trial relied on Brückner’s advanced BOPP production line combined with PureCycle’s proprietary solvent-based purification process, which transforms post-consumer polypropylene into a resin that closely matches virgin quality. This breakthrough arrives at a time when global packaging companies are facing mounting regulatory and consumer pressure to reduce plastic waste. Both the EU and the U.S. are tightening recycling targets and expanding extended producer responsibility (EPR) frameworks, raising demand for scalable, high-performance recycled materials.

If adopted more broadly, BOPP films containing PCR resin could play a crucial role in helping global brands meet sustainability goals without compromising on essential qualities such as food safety, labeling durability, and supply chain efficiency. Industry observers note that the collaboration between recycling innovators and technology providers will be key to building a more circular plastics economy.

Source: PureCycle Technologies